Ethical Manufacturing Matters: Otele Manufacturing

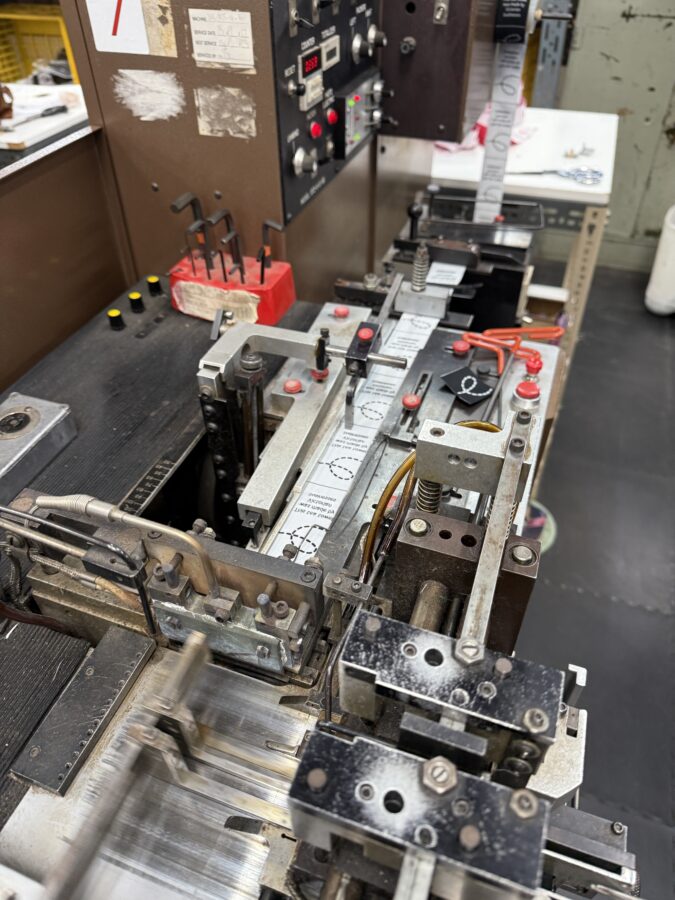

Newly accredited this year, Otele Manufacturing is an ethical manufacturer based in Western Sydney

Approximately 63% of their production is attributed to school uniforms, while the remaining 37% is attributed to emergency services, bands, sporting club and RSL uniforms. As part of our Ethical Manufacturing Matters series, we spoke to Sandra Hochuli, Director at Otele Manufacturing, about what it means to be accredited, the impact of local and ethical manufacturing, and how Otele continues to innovate while maintaining high standards.

What does it mean to be accredited by Ethical Clothing Australia?

Being accredited by Ethical Clothing Australia is a great achievement for Otele. It assures our staff and customers that we are not only legally compliant, but also genuinely committed to upholding ethical practices across every stage of our production — from fair wages and safe working conditions, to transparent supply chains and responsible sourcing.

How has our accreditation transformed the way you operate?

To achieve accreditation, we undertook a comprehensive audit and documentation of our local supply chain, including all sub-contractors. This process provided us with greater oversight, improved ethical compliance, and reduced operational risks. As a result, we’ve also expanded our team with two new employees and adapted our processes to better support our workers — including improvements that promote a healthier work/life balance.

You mentioned that the majority of your production is attributed to school uniforms, what are some of the challenges of manufacturing them in Australia?

School uniforms are price-sensitive products. Schools, parents, and education departments often prioritise affordability. This creates a tension between keeping prices low and ensuring that every person involved in the production is paid fairly and works in safe conditions. Increasing prices does put us at risk of losing customers to offshore manufacturers. This has happened often with past customers, particularly when schools are looking to cut costs and increase their own profit margins.

Can you share some of the benefits for schools when it comes to working with local and ethical manufacturers?

Working with local manufacturers means better communication and quicker service — this is especially helpful during busy times like the start of the school year. We can very quickly turn around urgent orders for our schools and there are better quality control systems in place, ensuring a higher quality garment. Issues can also be identified and resolved more quickly, reducing defective and inconsistent items. We can also provide services to the schools that offshore suppliers usually cannot, such as embroidery for special achievements and alterations for second hand uniforms or accidental damage.

Schools can feel confident knowing their uniforms are made by people in Australia who are paid fairly, work in safe conditions, and receive all their legal rights. This supports values like fairness and respect, which many schools already promote.

What impact does local and ethical manufacturing have on people, your business, and the industry at large?

For a start, fairer and safer working conditions for our employees means better health and well-being. It also prevents exploitation. Many outworkers—especially migrants or refugees—have in the past been underpaid and excluded from employee entitlements. Ethical manufacturing and auditing, help protect these vulnerable workers and sets a standard within the industry.

Within our business this impacts us by creating stronger brand reputation and consumer trust. Many consumers are moving more towards locally made, sustainable, and ethically sourced products. This has greatly strengthened our reputation amongst our customers and the community. In fact, most of the new business we receive is through word of mouth! It also allows us to work efficiently and to a high quality standard due to better quality control measures. The one downside however is maintaining competitive pricing against offshore manufacturers.

Within the industry at large, we can see economic growth with local manufacturing and new job creation, boosting domestic capabilities, supporting skilled trades, and contributing to a more resilient and self-sufficient economy.

What innovations are you implementing to improve efficiency while maintaining ethical standards?

Being able to produce locally has given us a high level of control over our production processes, allowing for greater flexibility, efficiency, and responsiveness in how we operate. As a direct result, we’ve successfully implemented a four-day work week with a three-day weekend — a shift that has had a profound impact on our team. This change has significantly improved our employees’ work-life balance, contributing to better physical and mental health, reduced burnout, and a more positive workplace culture. In turn, we’ve seen measurable improvements in productivity, focus and overall job satisfaction.

In an industry where it is becoming increasingly difficult to find and retain skilled local workers, prioritising the health, well-being, and morale of our team is not just an ethical decision — it’s a strategic one. Creating a workplace where people feel valued and supported helps us attract and retain talent, reduce turnover, and build a stronger, more resilient workforce.

Discover more ethical manufacturers like Otele Manufacturing here.

Related articles

Explore more insights, updates and stories from across Australia’s ethical and local manufacturing industry.