A Q&A with Cesar from Catuor

Cesar Tulande, director of the Brisbane-based manufacturer Catuor Pty Ltd, shares how he turns ideas into high-quality, Australian-made garments, and why Ethical Clothing Australia accreditation matters for transparent local production.

Hi Cesar! Tell us a bit about yourself.

I’m an Australian who was born and raised in Colombia. Sewing has been part of my life for as long as I can remember. It was a family trade, and from a young age I was regularly involved alongside my father in our small family business. It wasn’t formal training, but practical, day-to-day learning that taught me the importance of care, consistency, and taking pride in the finished work.

Those early experiences shaped how I approach manufacturing today. I have a deep respect for the skill involved and for all of us doing the work.

I’m now based in Wavell Heights, Brisbane, where I run Catuor Pty Ltd, combining those foundations with more than a decade of professional experience in the Australian garment industry.

For someone discovering Catuor for the first time, how would you describe what you do?

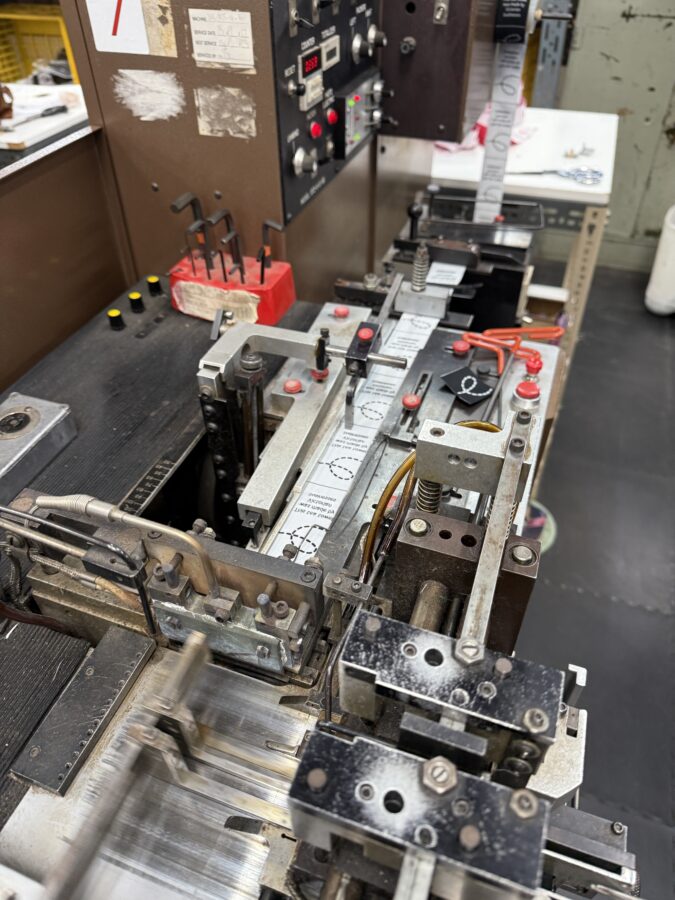

Catuor is an Australian-owned and based sewing and garment manufacturing business. We work with designers, brands, sporting organisations, and institutions to turn ideas into well-constructed, reliable garments, all made locally.

Operating as an Australian manufacturer comes with real challenges, particularly in a market shaped by low-cost offshore production that often relies on mass manufacturing models with limited protections for workers. Rather than trying to compete on price alone, our focus is on what we can do better: quality, consistency, and turnaround times that clients can rely on. We provide end-to-end manufacturing, from sampling and prototyping through to bulk production, with close attention to construction and finish at every stage.

By manufacturing onshore, we’re able to respond quickly, maintain strong quality control, and keep skilled jobs in Australia, by Australians. We take the time to understand how a garment will actually be used and help clients make informed decisions, so the final product performs properly in the real world, not just on paper.

Sewing has been part of my life for as long as I can remember.

- Cesar Tulande | Director of Catuor Pty Ltd

What first drew you into sewing and garment manufacturing, and what made you decide to build a career in it?

Sewing was part of everyday life for me growing up, so it never felt separate from who I was. From a young age, I loved making things with my hands and seeing an idea turn into something real. That enjoyment never left. Over time, I came to understand just how much technical skill sits behind a well-made garment. It’s creativity, yes, but it’s also problem-solving, precision, and a deep understanding of materials and construction.

What really kept me in the industry was how much I enjoy the process itself. I love creating, and I love helping others create. Whether it’s refining a design, improving a construction detail, or solving a production challenge, there’s real satisfaction in knowing the final garment works better because of those decisions.

As I gained experience in professional manufacturing roles, I realised this was where my strengths and passion aligned. I enjoy lifting quality, improving processes, and making garments that last. That combination of craft, purpose, and collaboration is what made me commit to garment manufacturing as a long-term career.

Rather than trying to compete on price alone, our focus is on what we can do better: quality, consistency, and turnaround times that clients can rely on.

- Cesar Tulande | Director of Catuor Pty Ltd

Was there a moment (or problem) that convinced you it was time to start Catuor—what was happening then, and what did you want to do differently?

Before starting Catuor, I worked in a range of production roles across different clothing manufacturers. That experience gave me a strong understanding of scale, systems, and commercial realities, but it also highlighted gaps within the industry.

I saw how heavily the sector relied on low-cost offshore production models, and how that reliance often came with trade-offs around quality, labour conditions, and environmental responsibility. I witnessed significant waste, compressed timelines, and a lack of accountability once production was moved offshore. Manufacturing was frequently treated as the final step, rather than something that should meaningfully inform design and decision-making from the outset.

That was the point where I realised there was real opportunity to do things differently. I wanted to build an Australian-owned and Australian-made business that could compete on quality and reliability, while employing local people and keeping skills and jobs onshore. A business grounded in considered production, rather than cost-driven shortcuts.

Catuor was created to be collaborative and transparent. I wanted clients to feel informed and supported, to understand their options, and to be confident that their garments were produced ethically, responsibly, and to a high standard. Improving ethical and sustainable outcomes wasn’t an add-on for me, it was the reason the business was established in the first place.

What did the first year of Catuor look like? What surprised you most about moving from manufacturing work into running a manufacturing business?

Starting Catuor felt a lot like raising a child. In the beginning, you’re doing everything yourself. You’re nurturing it, guiding it, losing sleep over it, and constantly adjusting as it grows. If you want it to thrive, you need real commitment, drive, and a willingness to put in long hours to get things right. Also, sewing, sampling, quoting, scheduling, and speaking directly with every client.

What surprised me most, though, was just how hard it is to start and sustain clothing manufacturing in Brisbane today.

There are very few practical, well-supported pathways left for people to learn sewing as a trade in Australia. While some qualifications technically still exist, access is limited and they rarely function as a clear pipeline into industry. Apprenticeship-style pathways for garment production are largely unavailable, and there is little structured support through TAFE that aligns with real manufacturing needs.

As a result, the only realistic option is to train people on the job, without formal assistance, or to try to find Australians who already have sewing experience, which is increasingly difficult. I also explored whether sewing could provide opportunities for new Australians, but industrial sewing is not recognised on skilled occupation or migration lists, despite the ongoing workforce shortages across the sector.

These challenges have reinforced why this work matters. Manufacturing isn’t just about making garments. It’s about keeping skills alive, creating genuine pathways, and guiding people, whether they’re clients or future workers, so problems are addressed early and the industry can grow in a more sustainable and ethical way.

Improving ethical and sustainable outcomes wasn’t an add-on for me, it was the reason the business was established in the first place.

- Cesar Tulande | Director of Catuor Pty Ltd

What is Catuor best known for today, and what kinds of work would you like to be known for in the next few years?

Catuor is best known for precision sewing, reliability, and the ability to work across a wide range of garments, including sportswear, uniforms, and custom apparel. Clients often come to us when quality matters, when timelines are important, or when designs need technical refinement to work properly in production. From the beginning, I’ve been intentional about building Catuor around reliability, quality, and keeping our promises, and that’s something I want to protect and strengthen well into the future.

Looking ahead, I’d like Catuor to be known as a trusted, long-term manufacturing partner for brands that value ethical production, strong construction, and consistency. I also hope to play a role in advocating for the future of Australian manufacturing more broadly. Keeping skills and training alive is critical, and I’d love to see stronger partnerships between industry, training providers, and even immigration pathways to support this. Without real investment in people and skills, Australian-made clothing simply won’t exist, and that’s something worth protecting.

When a new client approaches you, what information helps you give the most accurate advice early on (e.g., product goal, end-user, budget, target quantity, timeline)?

Understanding the product goal and end-user is the most important starting point. From there, information about budget range, target quantities, timelines, and whether sampling or revisions are expected helps us give realistic and accurate advice.

Clear communication early on prevents unnecessary changes and helps everyone stay aligned with the vision.

I’d like Catuor to be known as a trusted, long-term manufacturing partner for brands that value ethical production, strong construction, and consistency.

- Cesar Tulande | Director of Catuor Pty Ltd

Can you walk us through your typical workflow—from first enquiry through sampling, production, finishing and delivery—and where the biggest risks usually appear?

Our workflow is structured to identify and manage risk as early as possible. It begins with a detailed design discussion, where we work closely with clients to understand the garment’s purpose, end use, and performance requirements. This stage is critical, as unclear design intent or unrealistic expectations are where most downstream issues originate.

From there, we move into pattern development and sampling. This is where ideas are tested in a practical way, allowing fit, comfort, construction, and durability to be assessed before production decisions are locked in. We treat sampling as a risk-management step rather than a formality, and additional sampling is encouraged when needed rather than rushed.

Once a sample is approved, specifications are finalised and production is planned. Manufacturing is completed in-house with our own team, which allows for close oversight, consistency, and early intervention if issues arise. Having direct visibility across cutting, sewing, and finishing significantly reduces quality and compliance risks.

The highest risks almost always appear at the early stages, particularly when designs haven’t been properly tested or when technical details are vague. By slowing down the design, pattern, and sampling phases, we reduce waste, prevent rework, and ensure production is stable, predictable, and ethical once it begins.

What are the most common “fixable” issues you see in early designs or tech packs, and how do you help clients improve them before they become expensive mistakes?

Common issues include seam placements that won’t hold up in wear, missing tolerance details, fabric choices that don’t suit the garment’s purpose, or finishes that aren’t production-friendly.

We work closely with clients to explain these issues and suggest practical alternatives that improve durability, comfort, and production efficiency.

Our workflow is structured to identify and manage risk as early as possible.

- Cesar Tulande | Director of Catuor Pty Ltd

What quality markers do you personally look for in a garment (construction, tolerances, finishes, durability), and how do you build those checks into production?

When I assess quality in a garment, I look beyond how it appears on a hanger. Stitch consistency is one of the first things I notice, not just visually, but in how it holds under movement and wear. Seam strength, alignment, and balance are critical, especially in garments designed for performance or regular use. I also pay close attention to how a garment behaves when worn, how it stretches, recovers, and moves with the body, because that’s where good construction really shows.

Finishing details matter just as much. Clean hems, reinforced stress points, well-executed bindings, and tidy internal finishes all contribute to durability and comfort. These are often the details that get overlooked, but they’re the difference between a garment that lasts and one that fails prematurely.

Quality isn’t something we check at the end, it’s something we build in from the start. We embed quality checks at every stage of production, from sampling and pattern refinement through to cutting, assembly, and final inspection. Addressing issues early protects the integrity of the garment, reduces waste, and ensures the final product meets both our standards and the expectations of the client and end user.

What have been the biggest challenges you’ve faced running an Australian manufacturing business, and what has been the most rewarding highlight so far?

One of the biggest challenges has been shifting perceptions about Australian manufacturing, particularly around cost and capability. There’s still a common assumption that local manufacturing can’t compete, or that it’s limited in what it can produce. In reality, many people are surprised when they see what can be achieved onshore in terms of quality, speed, and technical complexity.

The most rewarding part, without question, is the personal satisfaction that comes at the end of the process. There’s a real sense of pride when you see a garment finished properly, knowing the care, problem-solving, and skill that went into it. Even more so when you see how pleased the client is, and then how happy the end user is when they wear it and it performs exactly as it should.

That moment makes the long hours worthwhile. It’s a reminder that manufacturing isn’t just transactional, it’s deeply human. You’re helping someone bring an idea to life, you’re supporting their vision, and you’re doing it in a way that aligns with your values. Knowing those garments were made ethically, locally, and with care adds another layer of meaning, and that’s what keeps me motivated to keep building and improving the business.

Manufacturing isn’t just transactional, it’s deeply human.

- Cesar Tulande | Director of Catuor Pty Ltd

Congratulations on becoming newly accredited! What does Ethical Clothing Australia accreditation mean to you, and what do you hope it signals to brands and consumers?

Ethical Clothing Australia accreditation means a great deal to me, both personally and professionally. It reflects the way I’ve always believed manufacturing should be done: fairly, transparently, and with genuine respect for the people behind the work. For me, ethical production isn’t a label or a trend, it’s about accountability, doing what you say you do, and being prepared to stand behind your practices.

Sustainability is a big part of that, but not just from a resources perspective. Of course, reducing waste, reusing materials where possible, recycling, and making thoughtful production decisions all matter. But sustainability, to me, also means protecting skills and knowledge. If we don’t actively keep sewing, pattern-making, and garment construction skills alive in Australia, then ethical manufacturing won’t exist here in the future, no matter how good our intentions are.

This accreditation recognises that ethical clothing is about people as much as product. It reinforces the importance of fair pay, safe conditions, and transparency, while also highlighting the need to invest in training, capability, and long-term pathways. I want Catuor to be part of putting plans and processes in place now, so ethical, Australian-made clothing continues not just today, but well into the future.

I hope Ethical Clothing Australia accreditation signals to brands and consumers that Catuor takes responsibility seriously at every level. Not only in how garments look or perform, but in how they’re made, who makes them, and how we protect the future of the industry.

Looking ahead, what are your plans for Catuor (capabilities, team, machinery, client types, product categories), and what would “success” look like 12 months from now?

Looking ahead, my vision for Catuor is about building something that lasts, not just a business that grows quickly. Over the next 12 months, I want to continue growing steadily and responsibly. That means investing in additional machinery where it genuinely improves quality and efficiency, and expanding the team in a considered way that protects standards, skills, and workplace culture.

Ethical production and sustainability will continue to sit at the centre of everything we do. Sustainability for me isn’t only about materials or waste reduction, although those things matter deeply. It’s also about people and skills. I want Catuor to be a place where sewing, pattern making, and garment construction knowledge is valued, shared, and kept alive in Australia. Without active investment in skills and training, ethical clothing manufacturing simply won’t exist here in the future.

I’m particularly passionate about creating pathways for people to enter the industry, whether that’s through on-the-job training, mentoring, or working with people who bring sewing skills with them as new Australians. There’s so much untapped talent, yet so few formal pathways left. I would love to see Catuor play a role in partnering with training providers, industry bodies, and even immigration and skills programs to help rebuild those pathways and keep the industry viable long term.

Success in 12 months wouldn’t just be measured by output or turnover. It would look like a business that’s known for reliability, quality, and keeping its promises. A team that feels proud of the work they produce. Strong, long-term relationships with clients who share our values. And progress, even if incremental, towards a more sustainable, ethical, and skilled Australian manufacturing industry.

If Catuor can continue delivering excellent work while contributing to the longevity of ethical clothing manufacturing in Australia, that’s success to me.

Ethical Clothing Australia accreditation recognises that ethical clothing is about people as much as product.

- Cesar Tulande | Director of Catuor Pty Ltd

Is there anything else you would like us to include in the article?

I’d like people to know that ethical and sustainable Australian clothing manufacturing isn’t something of the past. It’s alive, capable, and deeply valuable, but it does need to be actively supported if it’s going to continue. Behind every locally made garment are skilled hands, lived experience, and people who take real pride in what they do.

Ethical production and high-quality craftsmanship don’t exist by accident. They come from investment in people, fair working conditions, and a commitment to doing things properly, even when it’s harder. Choosing local manufacturing isn’t just a commercial decision, it’s a choice to protect skills, create opportunity, and keep knowledge alive for future generations.

I also hope we see greater recognition and leadership from government. There’s a real need for clear pathways and practical support to protect the industry and help it grow. That includes recognising sewing and garment manufacturing as valuable skills, supporting training and development, and creating opportunities for new Australians, skilled migrants, mums, dads, young people, and anyone looking to start fresh and build a meaningful career.

If we want Australian-made clothing to exist into the future, we need the right systems, support, and pathways in place now. That’s what Catuor stands for, and that’s the future I’m committed to helping build.

To learn more about Catuor Pty Ltd, visit their manufacturer listing in our directory and their website.

Related articles

Explore more insights, updates and stories from across Australia’s ethical and local manufacturing industry.